Custom scale model builder Gertjan Veld shows you one of his latest projects:

- Caterpillar D10T Dozer with Push Blade

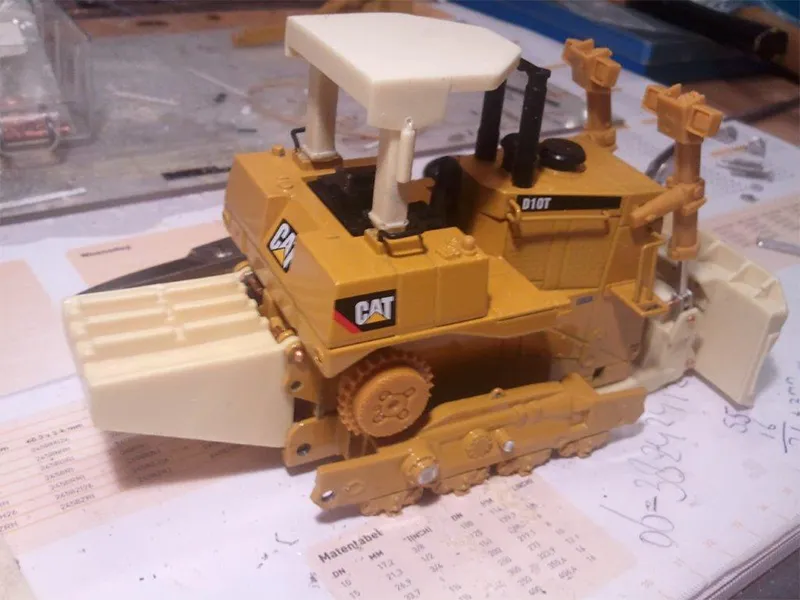

Gertjan shares his building skills through the photos with little notes guiding us in the construction process. Gradually it shows the making of a unique model by using the Caterpillar D10T Track-Type Tractor from Norscot and a resin Kit Push Blade in 1:50th scale to create his Caterpillar D10T Dozer with Push Blade.

Enjoy reading & watching!

Gertjan and Wouter

The Kickoff

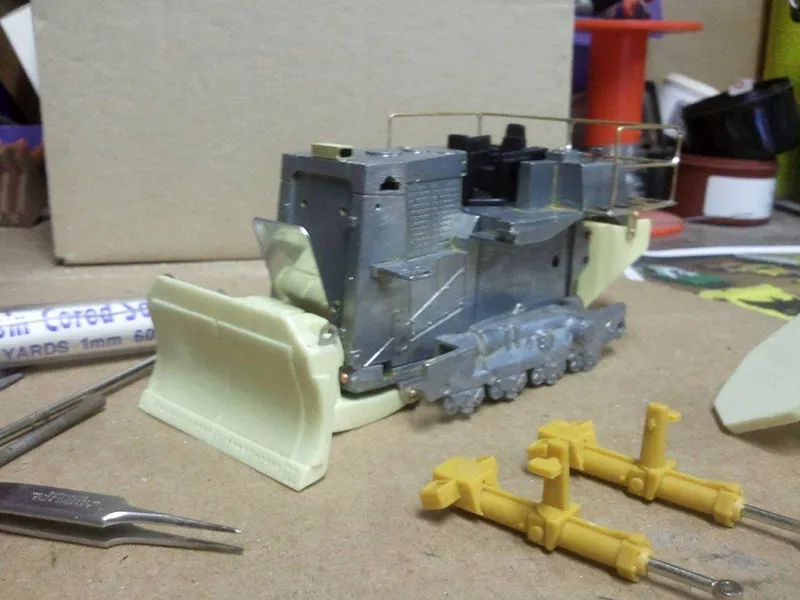

As a base for this project Gertjan uses the Caterpillar D10T Track-Type Tractor from Norscot and two resin kits from the Pusher Blade and the rear Counterweight in 1:50th scale which were purchased by Gertjan of Norbert Danchaud, a Frenchman on the Modelshow Europe, Ede.

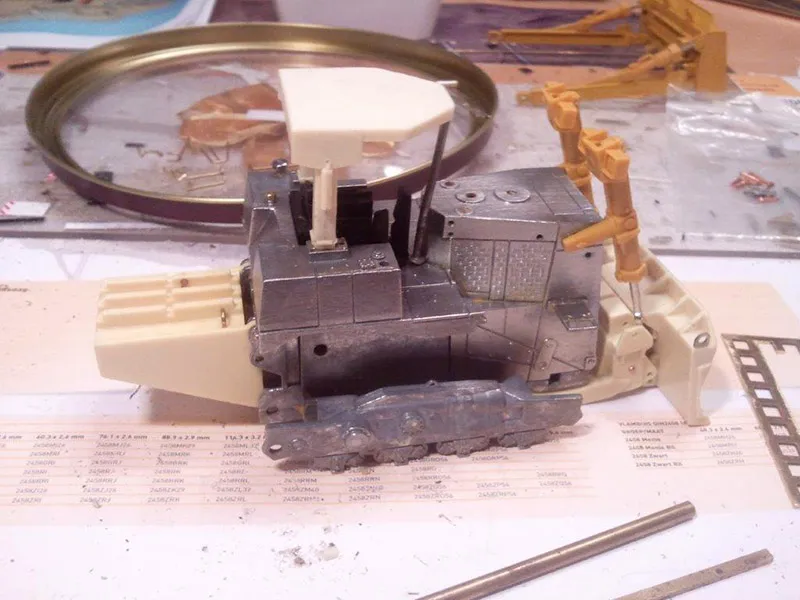

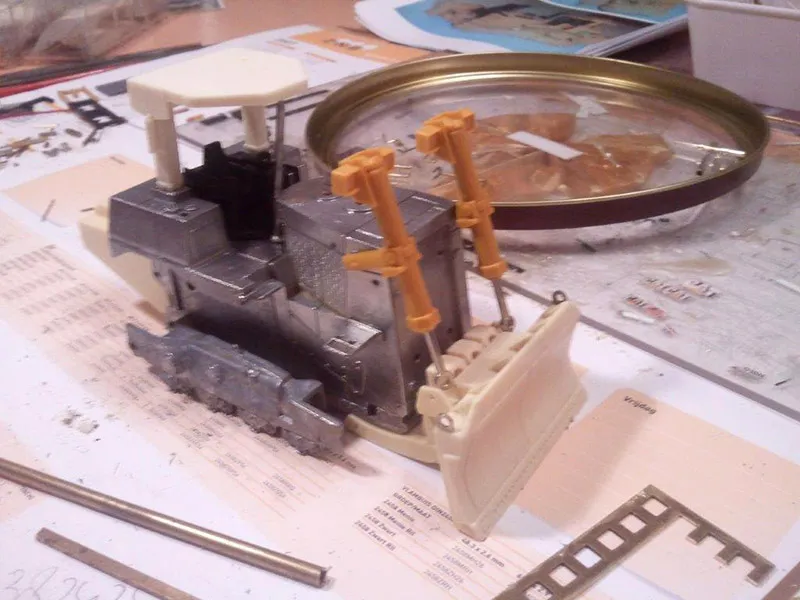

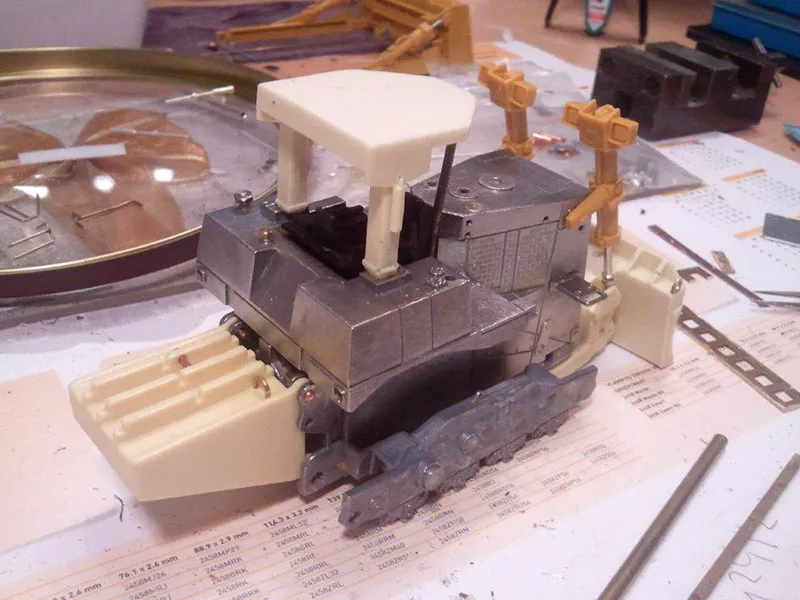

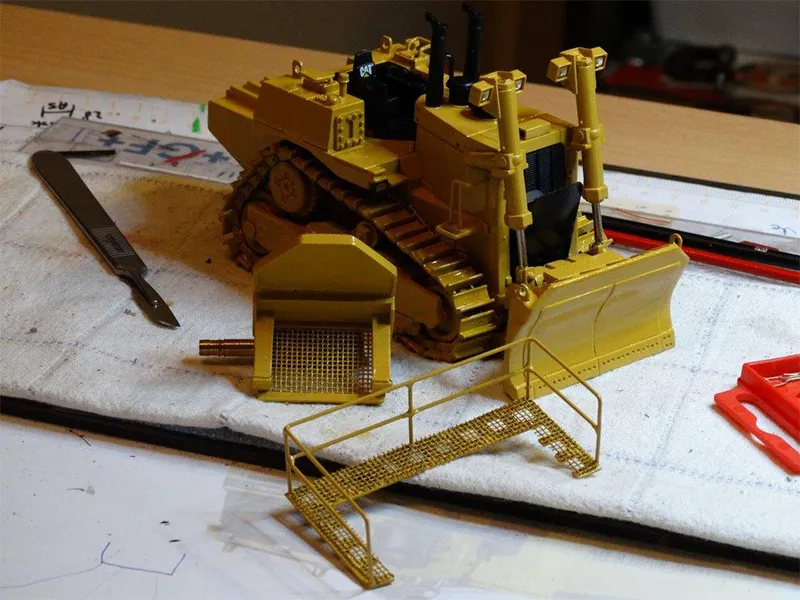

Gertjan starts with disassembling the Norscot basic model. Then all the components of the kits on the eye are settled so we already get a first impression of how the intended end result will ultimately come to look like.

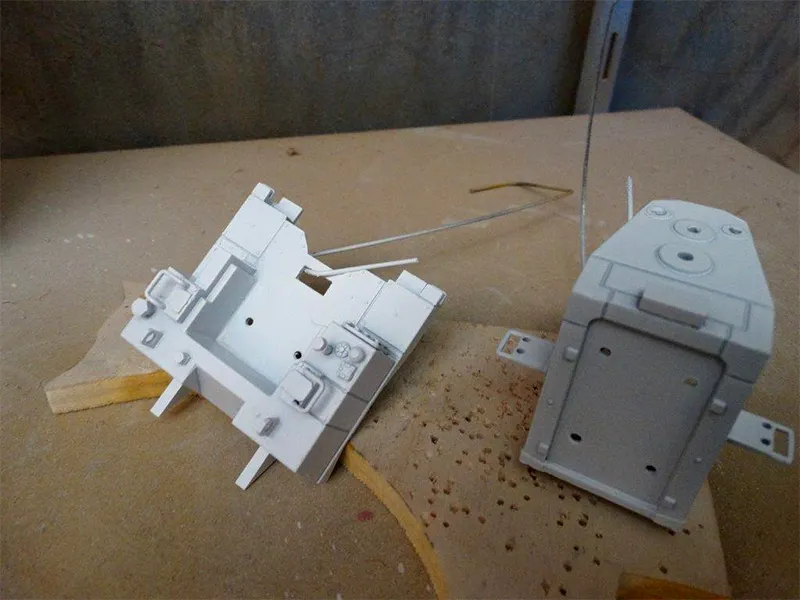

Work to be done! All components of the two kits are checked and, if necessary, deburred of casting scrap with the help of a file and soft sandpaper.

The Counterweight and the Push Blade kits

Because of all the changes and additions that will be required for this Caterpillar D10T Push Blade configuration to be build it is simply the best choice for the whole basic model all Caterpillar paint to discard so the model itself, resin kits and all the added details are completely bare and when we are finished the whole custom scale model looks tight and can be painted without any color difference.

This is of course at first a unthankful and tedious task, but it later delivers it a perfect final outcome. So its worth the effort.

The kit of the counterweight is equipped with various brass connections for the hydraulic hoses.

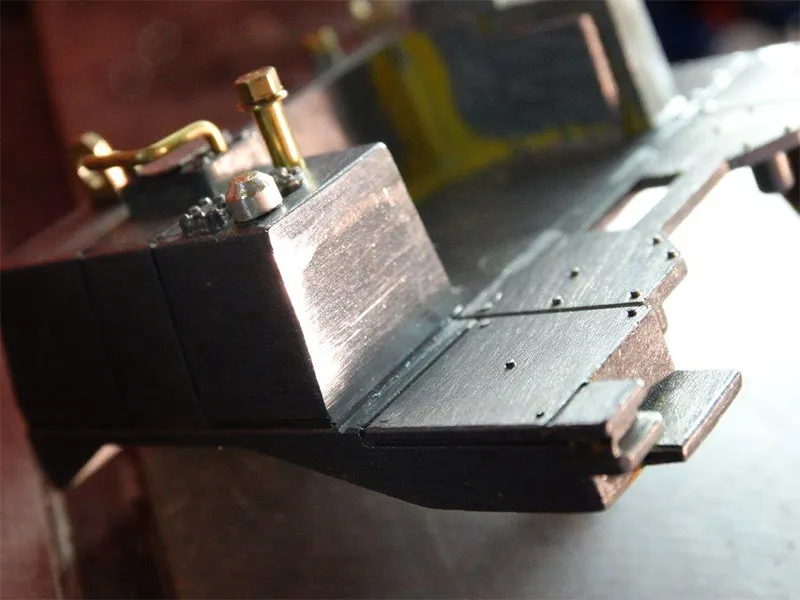

The kit of the Push Blade is provided with two metal hoisting eyes.

The hydraulic tank of the Track Type Tractor is provided with a proper brass filler cap.

The catwalk and the canopy

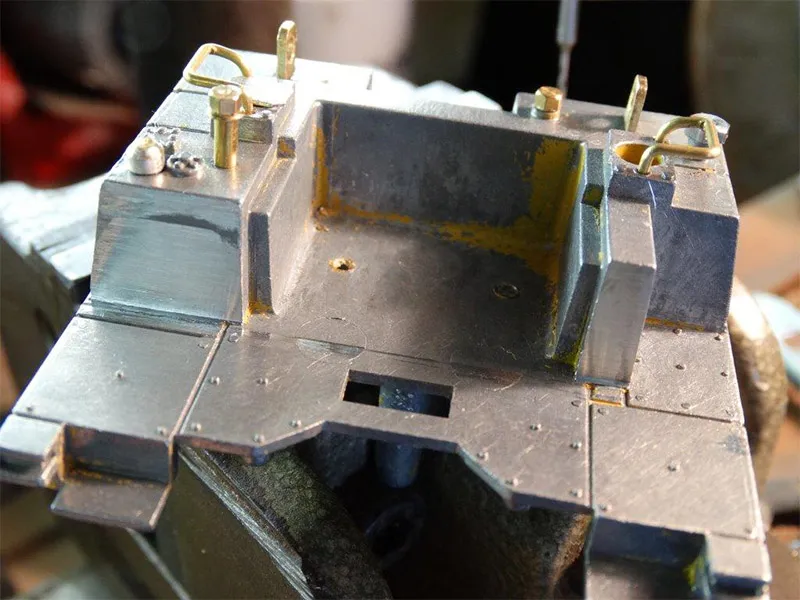

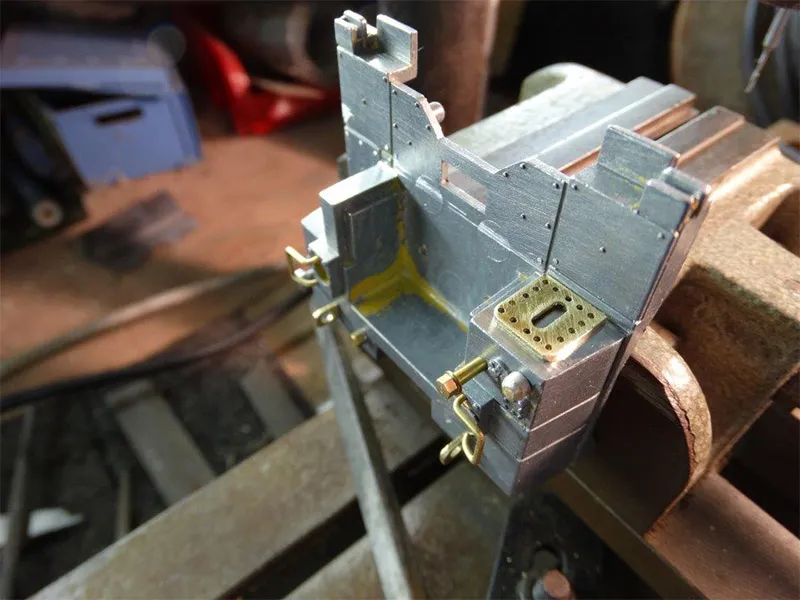

The Caterpillar Track-Type Tractor gets on the hood a metal block which will serve as the point of connection of the hydraulic hoses to the two lifting cylinders which will be added later during the building process.

GertJan constructs from brass material a completely from scratch built support construction and a catwalk around the rear of the superstructure of the Track-Type Tractor.

The kit of the canopy is equipped with a rear protection made from very fine mesh brass mesh material.

Finally, in this phase, Gertjan makes a correctly engineered fuel tank with a fuel filler cap made from brass material.

The hydraulic tank

The existing hydraulic tank is milled away at the front and filed smooth. And then Gertjan makes from brass material a completely new custom piece.

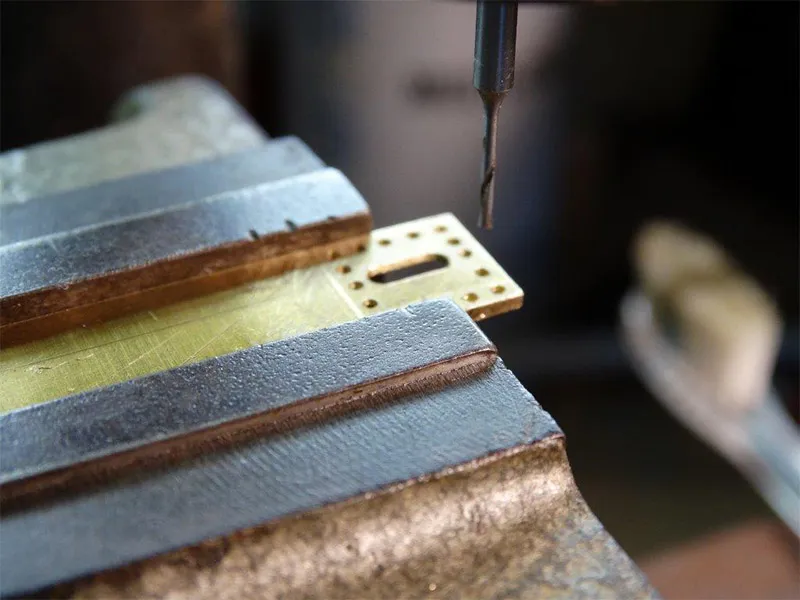

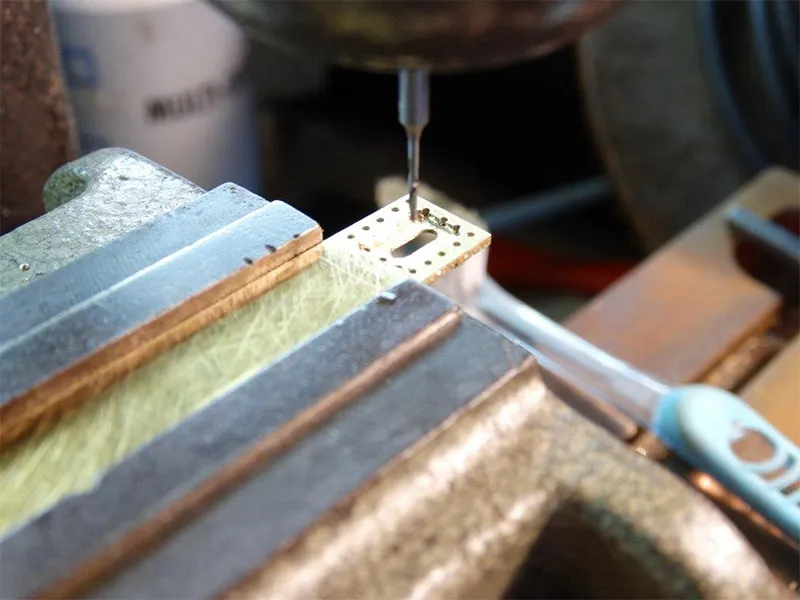

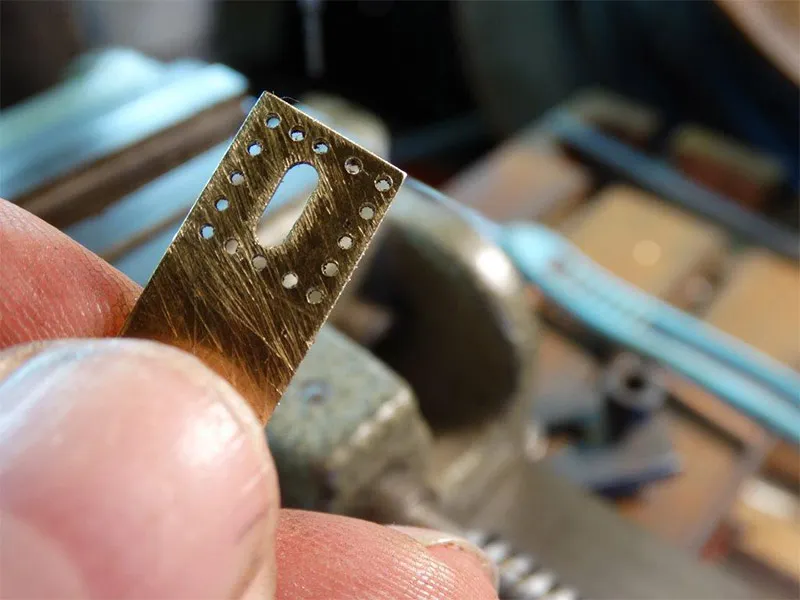

Gertjan makes on his milling machine of brass material, a completely new front side of the hydraulic tank. This front side is, as you can see, also provide the inspection glass for the liquid height.

And all his work delivers this small masterpiece as preliminary final result:

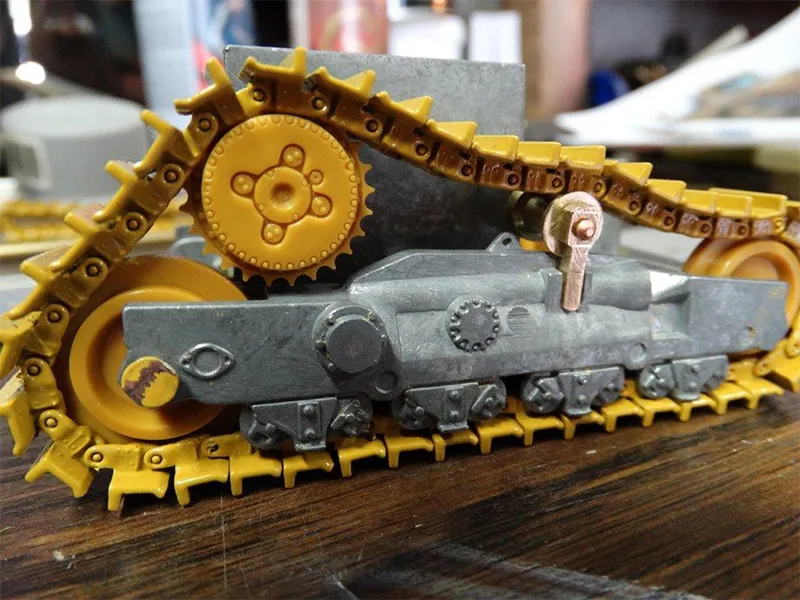

The Undercarriage

From the undercarriage the attachment points of the arms of the blade are removed. The lifting eye, which is casted completly closed on the original Caterpillar Track-Type Tractor by Norscot is made functional by drilling out the hole.

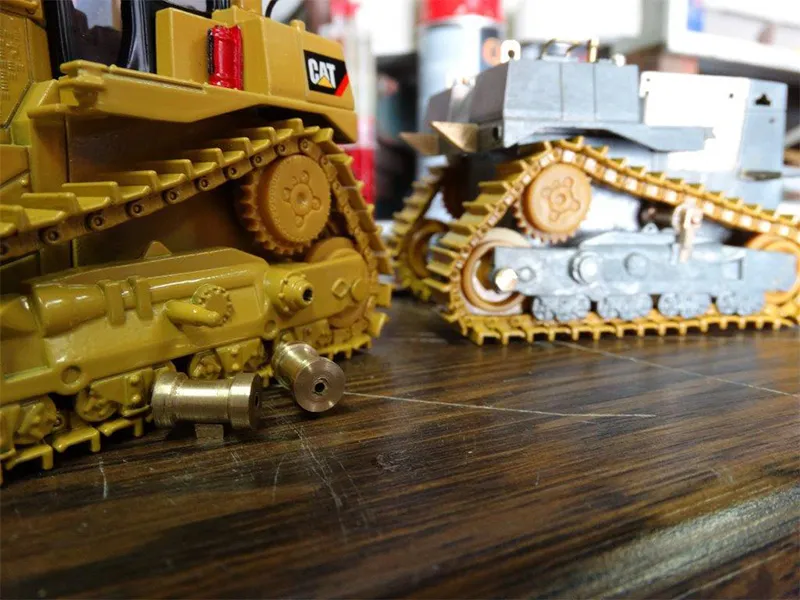

Most eye catching is that Gertjan adds the missing rollers on the undercarriage. Both rollers are fully hand crafted from brass material on the lathe.

Both rollers with their mounting frame are then placed on the undercarriage and glued to fix them on the right spot. The preliminary result is an undercarriage which directly looks much more realistically.

Gertjan was very pleased with the end result of this change and therefore decided that he also would adjust the undercarriage of his other custom Caterpillar D10T Track-Type tractor that was still standing in the cabinet and to provide this immediately on the same way with a pair of new rollers. So this creates a small extra little project in the "making of ..."; You will get therefore two for the price of one!!

This means of course that from this second Caterpillar D10T Track-Type Tractor the undercarriage also has to be resprayed, but thats no problem and can be combined and done at the same time with the other spraying jobs on the first the Caterpillar D10T Push Blade scale model.

The painting of the parts

The last step of the build-up phase is to test fit all the original and customized parts and after this finall test to clean up all the parts again with some lukewarm warm water provided with a little ammonia for degreasing.

After thoroughly cleaning with some lukewarm water with a little ammonia for degreasing let all parts, preferably at room temperature or even warmer dry. If necessary, place all parts briefly on a rack above the heating so the spray primer and paint adhere well directly on the resin or metal parts.

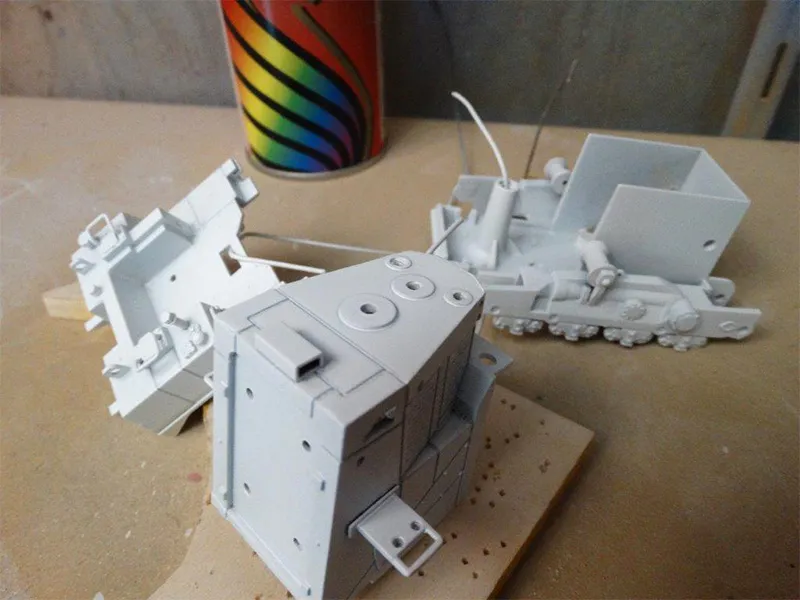

As a priming coat all parts are first put in the spray primer. Often this is a gray primer or a gray primer in which already has been added and mixed some drops of yellow paint to create the perfect ground layer to spray on your final color.

After spraying of the parts in the final paint layer, in this case, of course in original Caterpillar yellow, take enough time in order to let all parts under ideal conditions dry and curing. So keep your freshly painted parts free from dust under a dome or a keep them in a fully enclosed space. Preferably not in a cold hobby barn, but at a slightly warm room temperature to achieve the best adhesion of the paint.

So how difficult it might be, Do not touch! Do not waste all your work if you start to quick with the final assembly. Please kind in mind that how great the temptation is: Hands off!

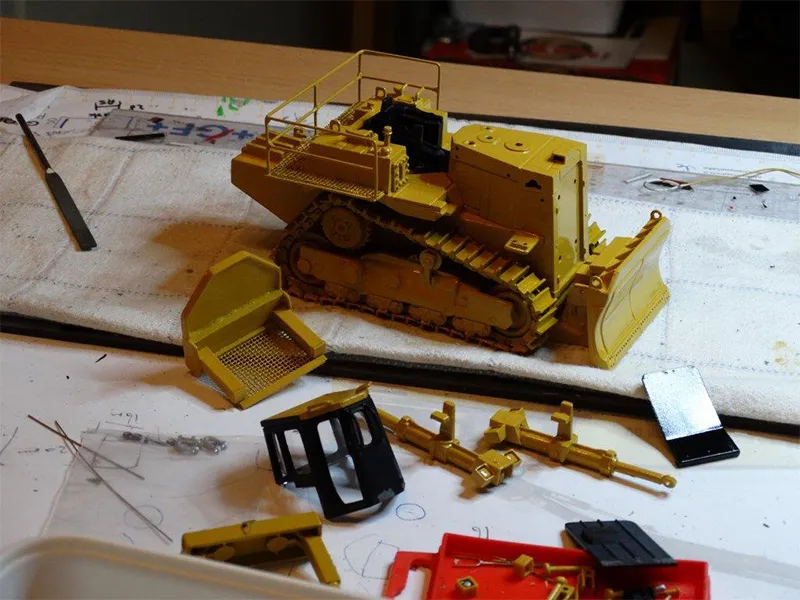

After keeping sufficiënt drying time Gertjan finally may start with the trial fitting of the painted parts.

During the assembling of the components it will be necessary to carefully scratch away some new added varnish for the perfect fit. Followed by finally reconnecting and assembling the painted parts to each other with the original screws or some glue.

The painted undercarriage and the covers for the removed lifting cylinders of the Caterpillar D10T Track-Type Tractor.

The Finall Step

On both machines there is extra work lighting applied to the lift cylinders, bottom at the side steps, the canopy roof and to the rear of the cab..

Of course, in the last phase also attentive to applying the correct lettering and type designations, so it will look that both machines just came off the assembly line of the factory and are delivered on their first jobsite.

Finally, the supporting structure and its walkway platform is attached at the rear of the upper structure of the Track-Type Tractor.

Dotting on the i are the fire extinguisher, shovel and a towing cable, which is made of a real steel cable purchased at the company Sauerbier Modelbouw , based at Zierikzee, the Netherlands.

Done!

Both models are now "Ready for work" and they can be added to the collection in the display cabinet.