In this "Making-of Hydex BH45 Block Handler Articulated Truck" we will show how this custom model will be achieved.

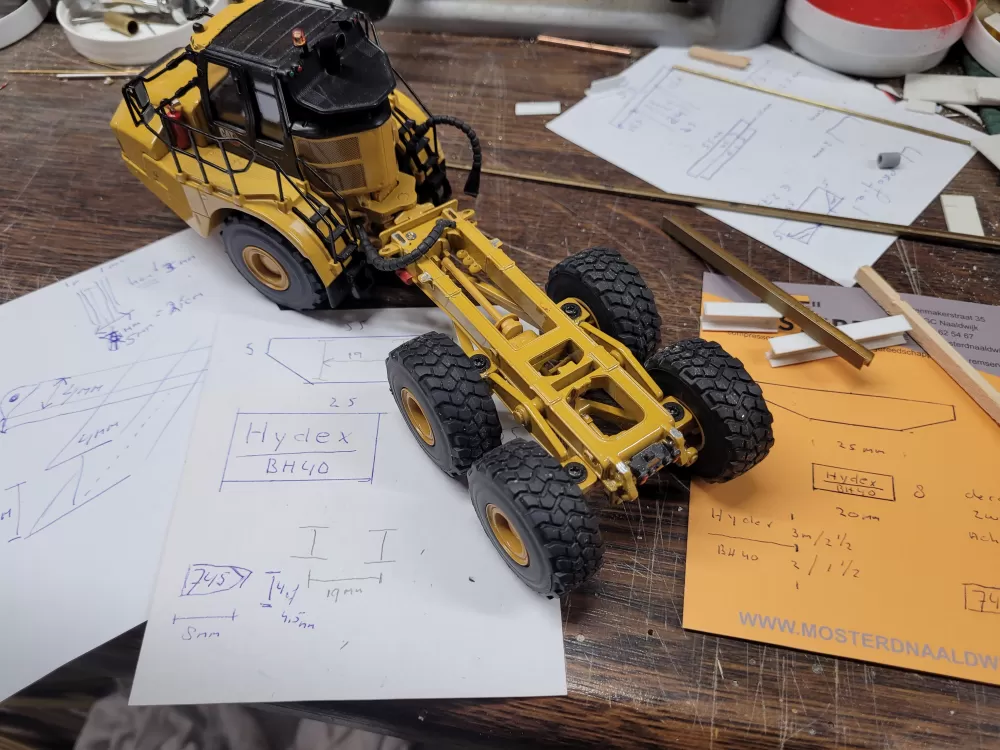

Gertjan shares his building skills through the photos with little notes guiding us in the construction process. Gradually it shows the making of a unique model by using the donor Caterpillar 745 "Next Gen" Articualted Truck from Diecast Masters in 1:50th scale to create his one of kind Hydex BH45 Block Handler Articulated Truck.

Enjoy reading & watching!

Gertjan and Wouter

What preceded

Gertjan is always looking for new custom projects based on (existing) Caterpillar scale models. When his eye fell on the special machines from the Hydex company, the idea was quickly born and he was able to start with the purchase of the Caterpillar 745 "Next Gen" Articulated Truck from Diecast Masters.

Hydex Solutions Ltd, founded in 1970 and HQ based in the United Kingdom, is a global leader in specialised application solutions for mining and construction equipment. Their motto: "TODAY’S ANSWERS, TOMORROW’S TECHNOLOGY" As OEM they have a broad product range which is based on a Caterpillar Articulated Trucks.

The Hydex BH35, BH40 and BH45 Block Handler has been specifically designed to transport mining blocks around the site easily and safely. Built around Caterpillar 35t, 40t and 45t articulated trucks the BH35, BH40 & BH45 enables operators to carry single or multiple blocks with a maximum payload of 32, 36.3 and 41 tonnes, thus maximising productivity.

The Kick-off

To build the Hydex B45 Articulated truck, Gertjan uses the latest Caterpillar 745 "Next Gen" Articulated Truck that was released by Diecast Masters under #85704 in 2021. Of course you can also buy the Caterpillar 745 Articulated Truck that was already produced in 2007 under #85528 by Diecast Masters.

The Caterpillar 745 dumper box is completely dismantled by carefully drilling through both lifting cylinders and the connections at the pivot point on the dumper chassis.

The Block Handler chassis

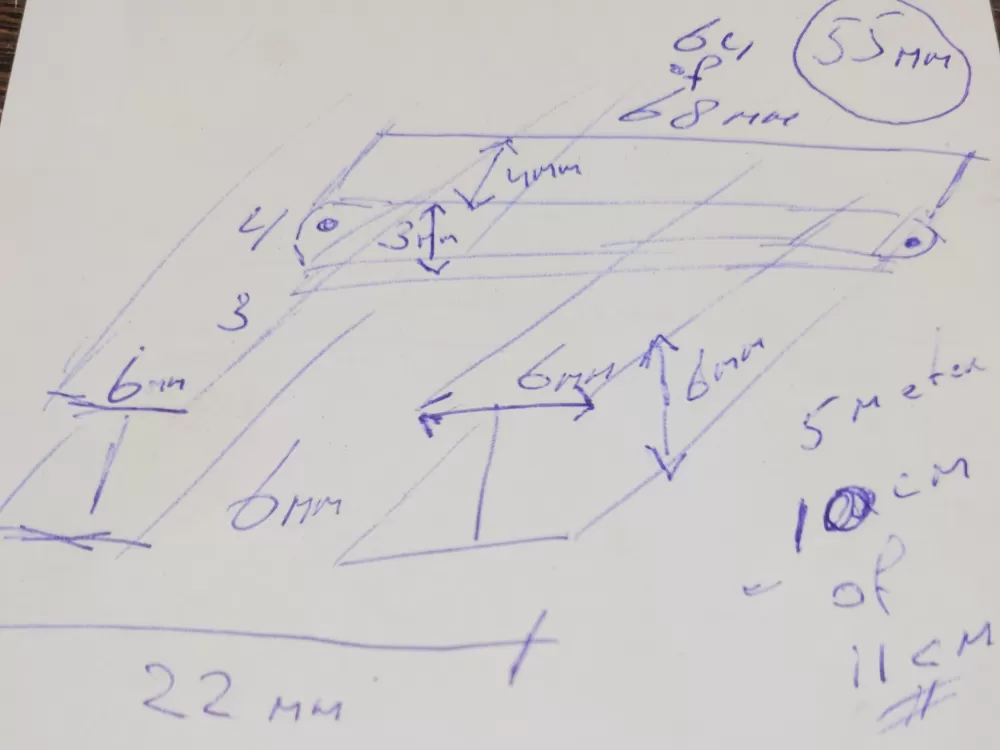

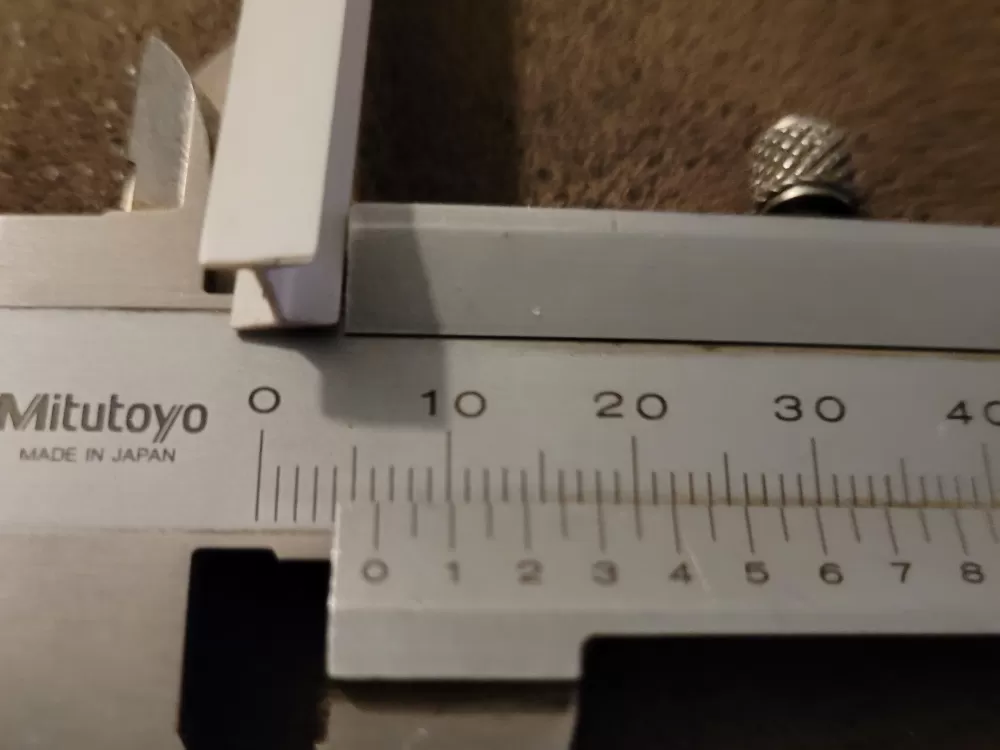

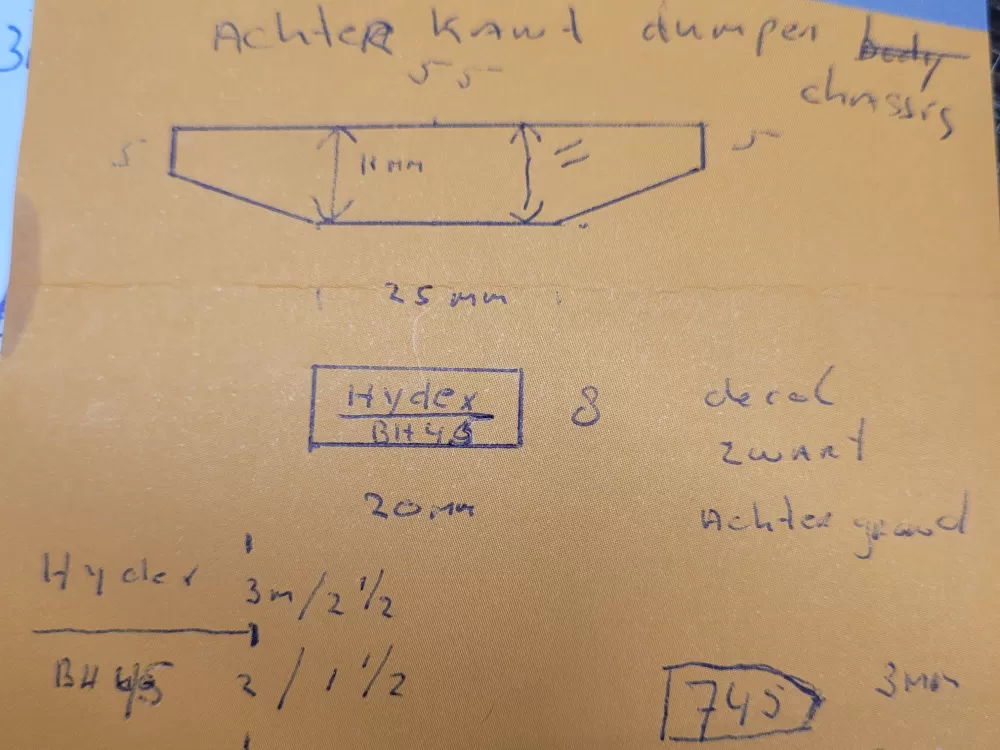

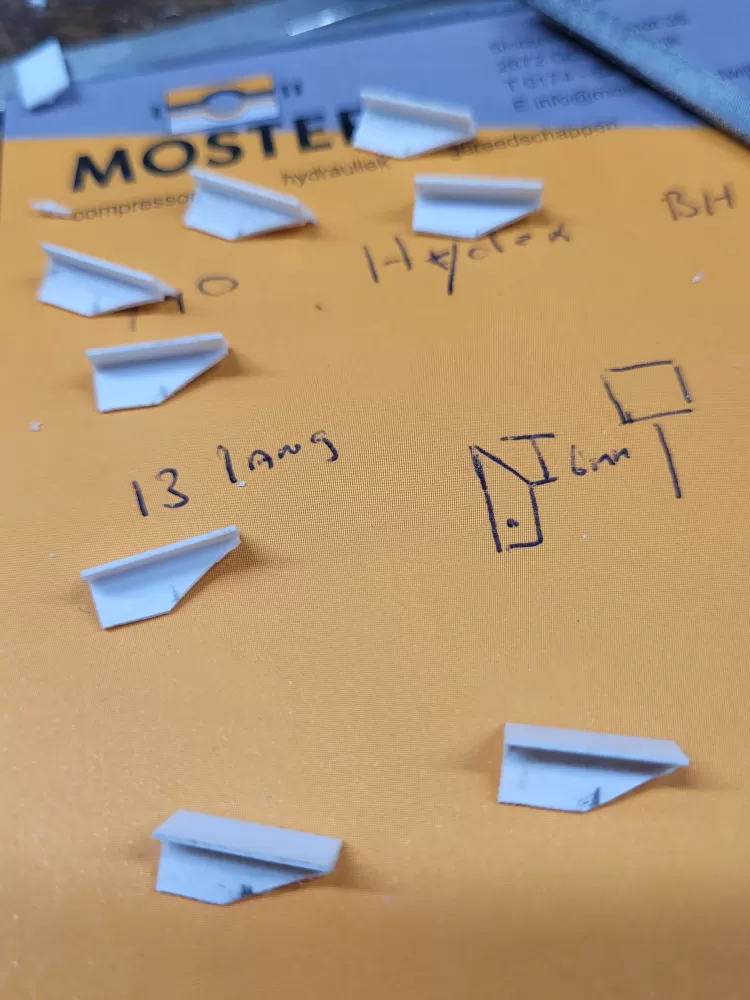

Good preparation is half the work. So measuring is knowing: Convert from 1:1 to scale 1:50 and the cutting and fitting for an exact replica can begin.

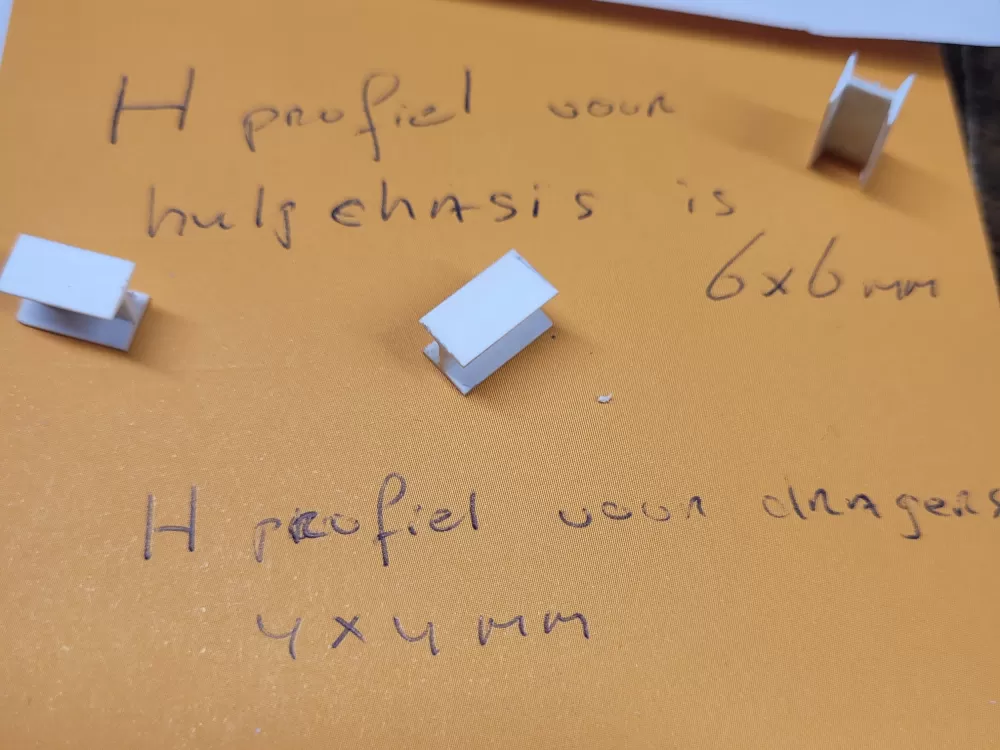

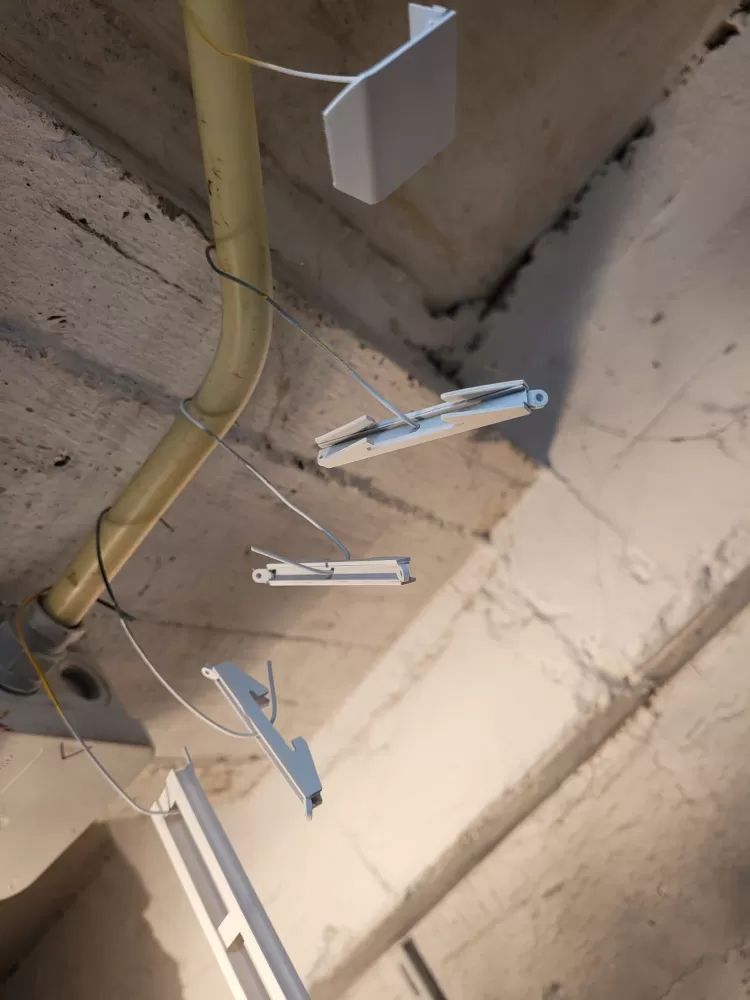

Based on the technical information from Hydex, Gertjan made the Block Handler sub chassis from plastic Evergreen H profiles in 6x6mm, which is mounted on the existing chassis of the Caterpillar 745 Articulated Truck.

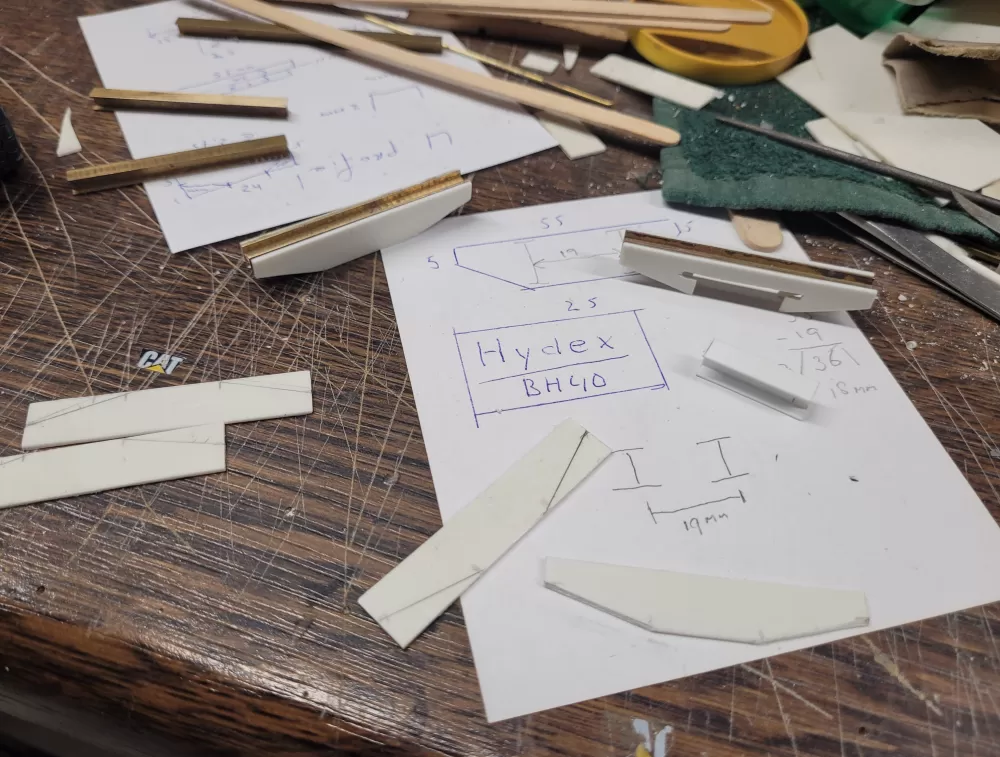

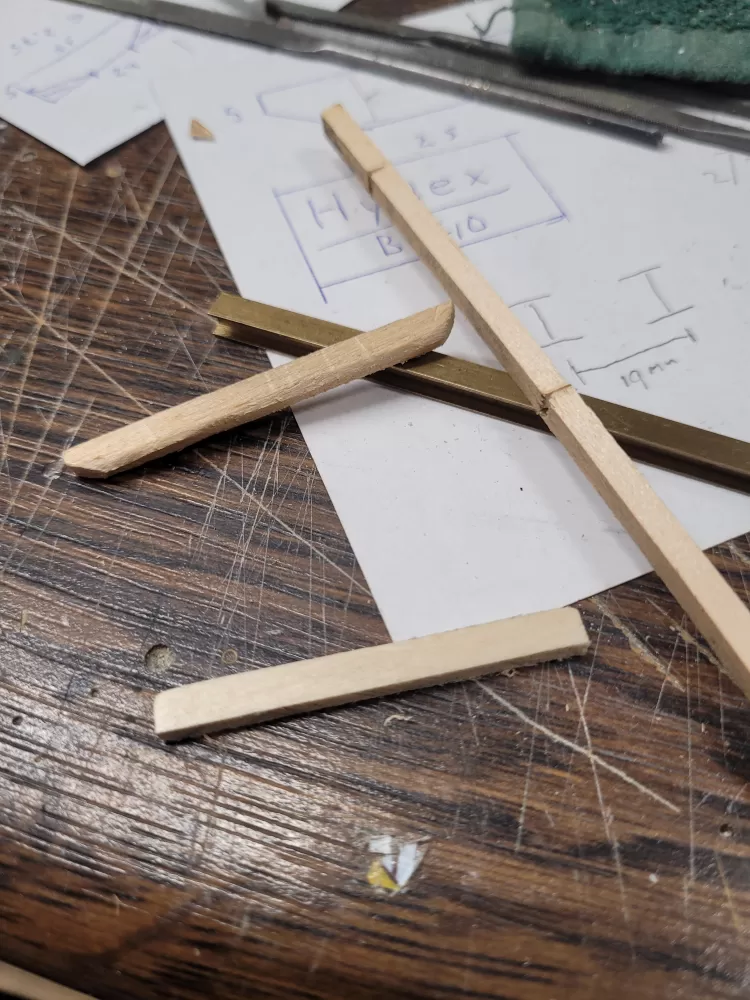

The four sleepers that will ultimately have to carry the heavy load are made from brass H 4x4 mm profiles that are shortened to the correct length and fitted with plastic Evergreen plate as plating.

Finally, large lashing eyes are mounted from plastic 3D printed material on each side of the four sleepers so that the load can be transported safely and securely. These lashing eyes were made at Gertjan's request by Paul Ogier of PO Miniatuurbouw.

The Structure for the load on the chassis

In order to transport the very heavy marble blocks as cargo safely and without damage, a number of extras have been added to the chassis.

Gertjan again opens his entire box of tricks to make the scale model a very realistic representation of the big 1:1 brother.

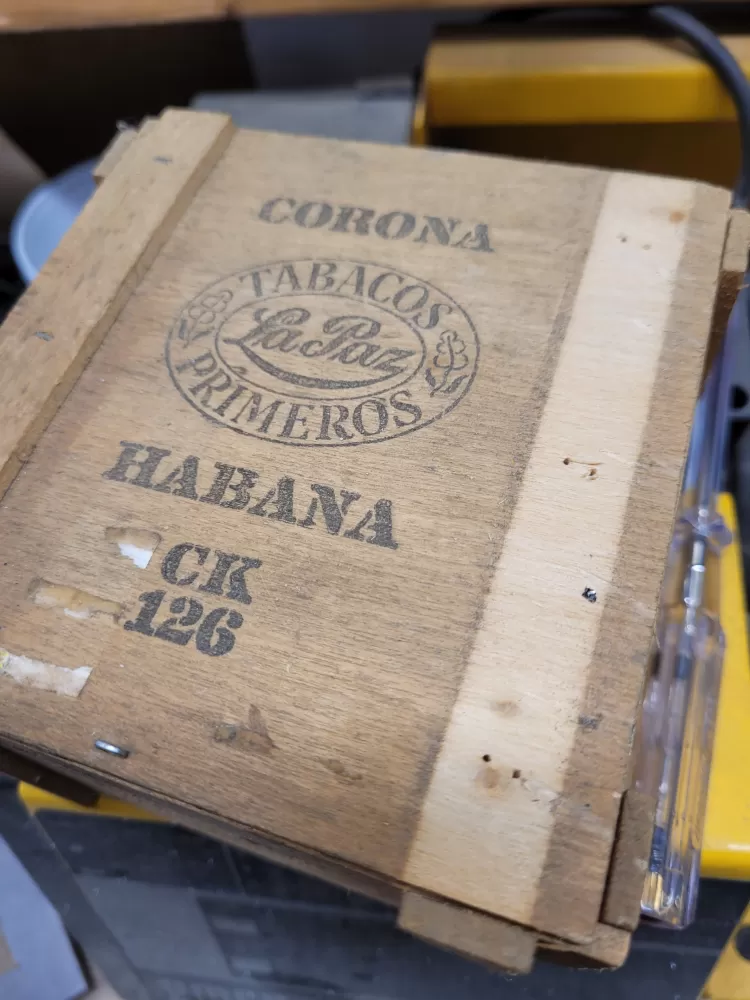

In his parts stash he found an old-fashioned wooden cigar box.

Ideal material for measuring, fitting and cutting to create four real wooden beams that ensure that the metal frame of the Hydex BH45 Articulated Truck is not damaged when loading and unloading the cargo.

To properly position the load before it is secured, Gertjan made the necessary spacers from Evergreen plastic H profiles.

Thanks to good model making precision tools, craftsmanship and a lot of patience, exact replicas of the spacers in scale 1:50 are cut from the plastic H profiles and mounted on the brass loading frame.

The painting of the parts

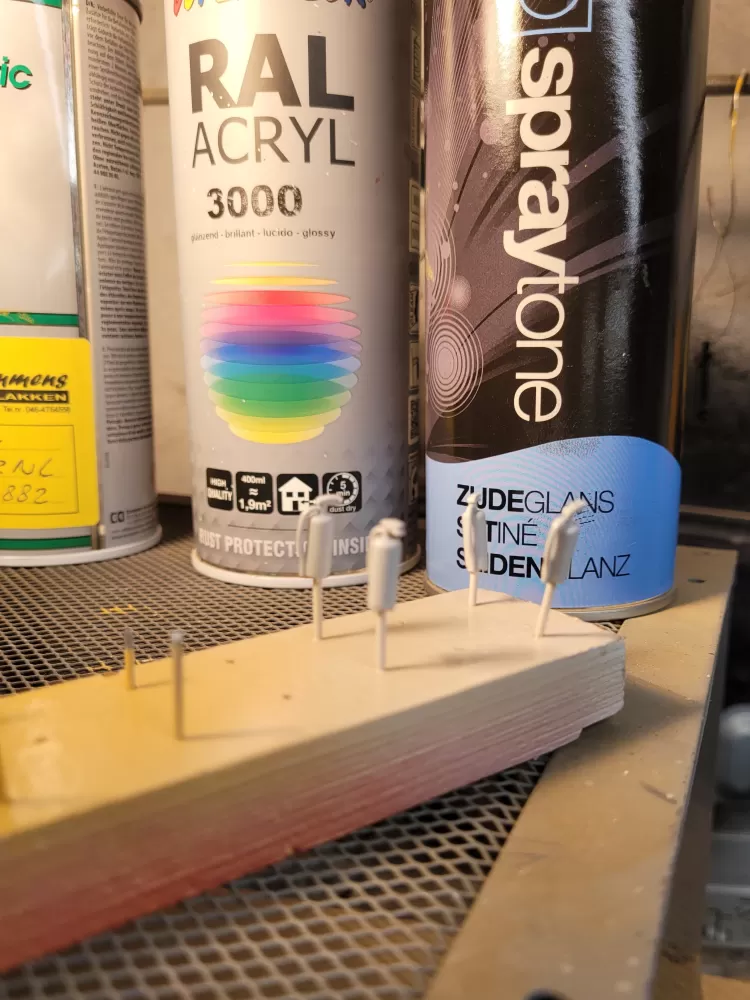

After thoroughly cleaning with some lukewarm water with a little ammonia for degreasing let all parts, preferably at room temperature or even warmer dry. If necessary, place all parts briefly on a rack above the heating so the spray primer and paint adhere well directly on the resin or metal parts.

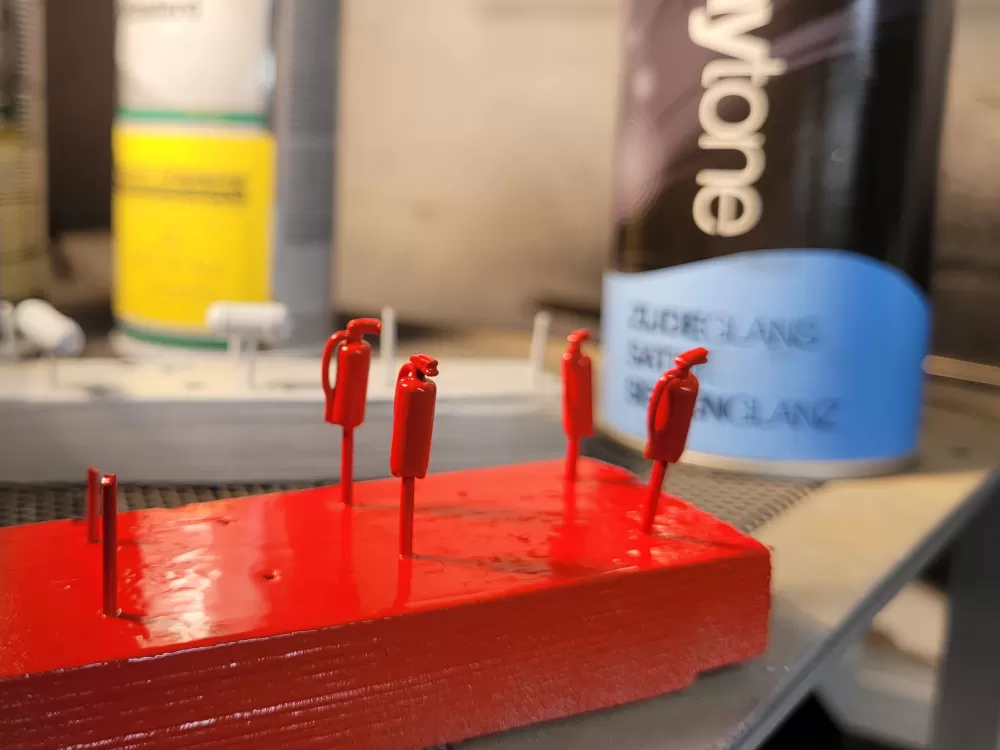

All parts, one by one are carefully hang in the spray cabin.

As a priming coat all parts are first put in the spray primer. Often this is a gray primer or a gray primer in which already has been added and mixed some drops of yellow paint to create the perfect ground layer to spray on your final color.

After applying the primer ample time to let out enough to harden all painted parts before starting the finishing with the final Caterpillar top coating.

Then follows the same ritual: cleaning, degreasing, preheating, hang up, final coating and allow to harden.

After spraying of the parts in the final paint layer, in this case, of course in original Caterpillar yellow, take enough time in order to let all parts under ideal conditions dry and harden. So keep your freshly painted parts free from dust under a dome or a keep them in a fully enclosed space. Preferably not in a cold hobby barn, but at a slightly warm room temperature to achieve the best adhesion of the paint.

Final assembly

So how difficult it might be, Do not touch! Do not waste all your work if you start to quick with the final assembly. Please kind in mind that how great the temptation is: Hands off!

Done!

The model is done and now "Ready for work" and can be added to the collection in the display cabinet.